Cakra Elektrolisis : Innovation in Pond Water Sterilisation to Improve the Quality of Indonesian Shrimp Farming

New Challenges for Indonesian Shrimp Farming

The Indonesian shrimp farming industry is facing its most challenging phase in the last decade. Pressure is coming from various directions: global price fluctuations, increasingly stringent export standards, and the emergence of new diseases that are difficult to control.

In the field, pond water health is one of the most crucial issues. Many farmers face the following conditions:

- High populations of Vibrio spp.

- Accumulation of harmful ammonia

- Unstable water quality

- High dependence on chemicals

- Decline in shrimp performance due to pathogen pressure

These conditions cause many ponds to fail to achieve optimal survival rates (SR) and feed conversion ratios (FCR).

In the long term, the use of chemicals as the main solution actually triggers new problems: pathogen resistance, high operational costs, and imbalance in the pond ecosystem. Therefore, the industry has begun to shift to water sterilisation technology that is more environmentally friendly, economical, and works automatically.

One solution that is now gaining widespread attention is electrolysis technology for pond water sterilisation.

What is Water Electrolysis for Shrimp Farming?

Electrolysis is an electrochemical process that uses electric current to break down chloride ions (Cl⁻) in water into active oxidising compounds, primarily hypochlorous acid (HOCl) and other active chlorine compounds.

HOCl has several important advantages in shrimp farming:

A very strong natural disinfectant

Safe for farmed biota in controlled doses

Effective in suppressing Vibrio spp. and opportunistic pathogens

Leaves no harmful chemical residues

Does not trigger resistance like conventional chemicals

With this mechanism, water quality becomes more stable, pathogen pressure decreases, and the pond environment is safer for shrimp growth.

Globally, electrolysis technology has long been used in the aquaculture industry. However, in Indonesia, its adoption is still limited. The presence of local innovation is an important momentum for the transformation of national intensive ponds.

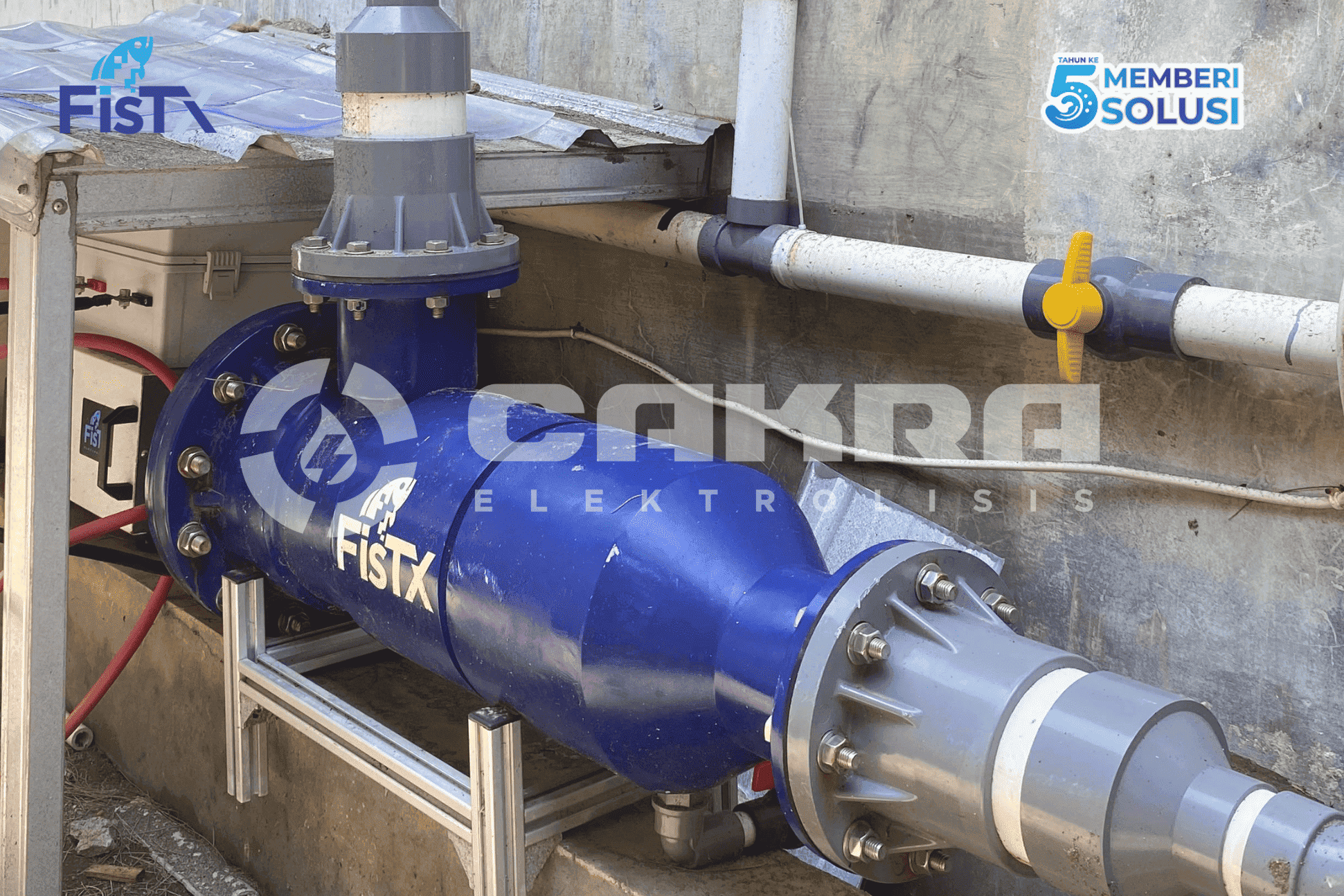

Cakra Electrolysis: Electrochemical Technology from FisTx for Modern Ponds

FisTx, an Indonesian aquaculture technology company, has developed Cakra Electrolysis as an electrochemistry-based water sterilisation solution for modern ponds.

This technology is designed as:

- An automatic biosecurity system

- A device to directly reduce pathogens in pond water

- A replacement for chemical sterilisation agents

- A 24-hour water quality stability maintainer

- Support infrastructure for intensive ponds

Cakra Electrolisis works without additional materials, using only electricity and aquaculture water. Active compounds are produced directly in the pond, making them more stable and faster to react.

This product has been tested in various pond conditions, including an official full-cycle test at the Samas Brackish Water Aquaculture Unit (UK BAP), under the Ministry of Maritime Affairs and Fisheries.

Full-Cycle Test at UK BAP Samas: Real-World Results

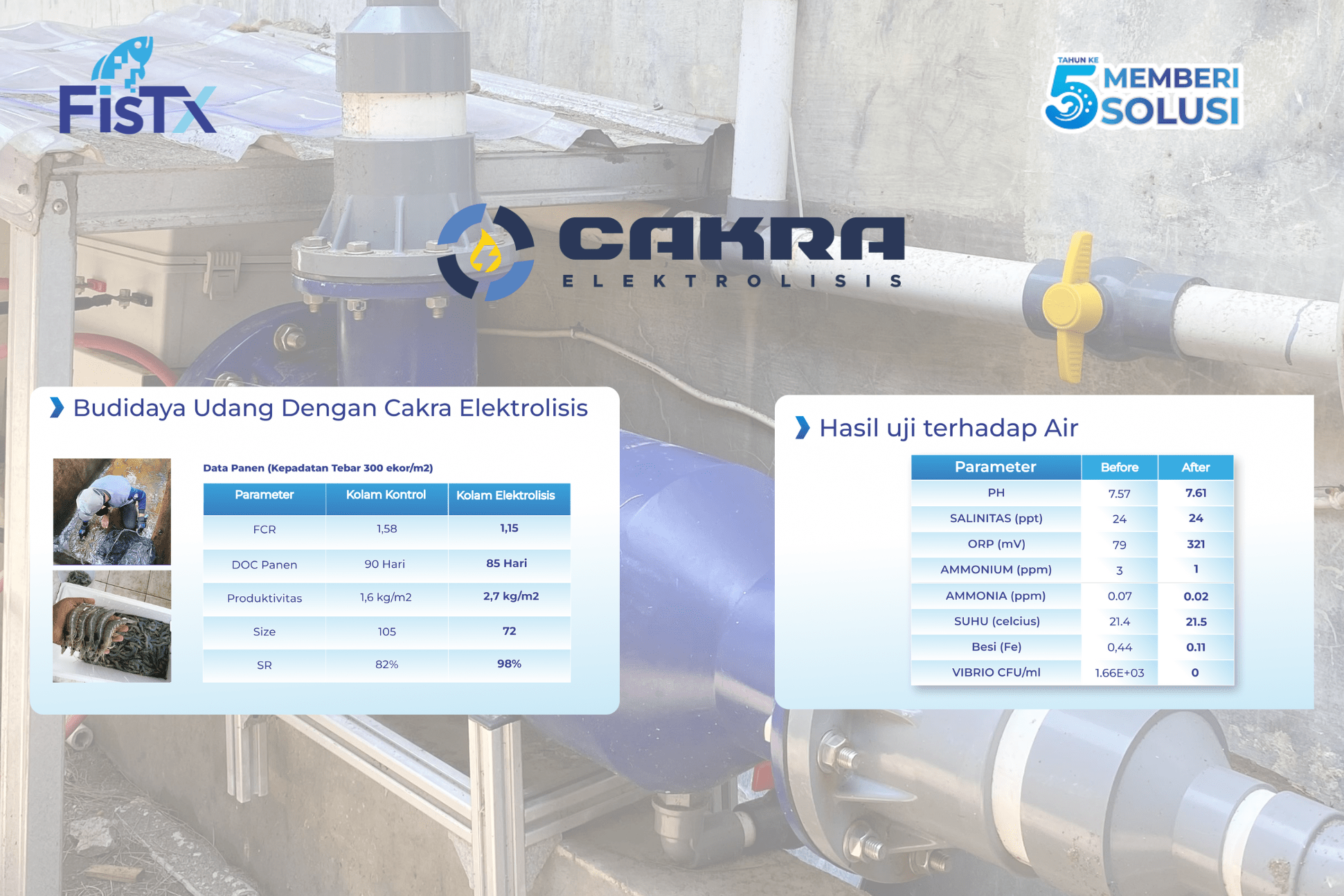

To demonstrate its performance, FisTx collaborated with UK BAP Samas in a full-cycle cultivation test in an intensive pond, compared to a control pond.

1. Significant Reduction in Vibrio

The head of the UK BAP Samas centre, Arga Kurniawan, stated:

‘This device is capable of reducing Vibrio in both water and hepatopancreas, thereby increasing the survival rate of shrimp to over 95%.’

The consistent reduction in Vibrio demonstrates the effectiveness of Cakra Electrolisis as a daily biosecurity system.

2. Survival Rate (SR) Increases to 95%+

The treated pond recorded an SR of over 95%, significantly higher than the control pond. In intensive farming, an increase in SR directly translates to higher harvest yields and profitability.

3. Stable and Increased ORP

The ORP (Oxidation Reduction Potential) value increased from 110 mV to 321 mV. High ORP indicates the water's ability to suppress biological contaminants and maintain a safe pond ecosystem.

4. Ammonia Reduced by up to 46%

The reduction in ammonia occurred due to:

Increased oxidation of organic compounds

Reduced pathogen load

Improved water circulation quality

Lower ammonia levels mean reduced stress on shrimp and more optimal growth.

5. FCR Reduced by up to 27%

Feed efficiency has improved significantly. The reduction in Feed Conversion Ratio (FCR) indicates that shrimp are able to utilise feed more effectively.

6. Lower Operational Costs

The cost of using Cakra Electrolysis is recorded at only £134/m³ per cycle, or approximately 89% more economical than using chlorine.

7. Attractive ROI

The projected Return on Investment (ROI) is around 1.8 years, making it viable for both intensive and semi-intensive ponds.

What Do Industry Experts Say?

National shrimp industry figure Hasanuddin Atjo emphasises the importance of water sterilisation innovation:

‘Water sterilisation infrastructure based on technologies such as UV and electrolysis needs to be continuously promoted so that the industry no longer relies on chemicals.’

Rico Wibisono (CEO of FisTx) stated:

“We want pond water to not only be clean, but also actively protective. Cakra Electrolysis enables biosecurity without chemical dependency.”

Why is Electrolysis the New Standard for Modern Ponds?

There are three main reasons:

1. 24/7 Active Biosecurity

Electrolysis works continuously without interruption.

2. Supports Global Export Standards

Minimal chemical residues, safe for international markets.

3. Operational Efficiency

Lower costs with more stable results.

Applications of Cakra Electrolysis in Aquaculture

Cakra Electrolysis can be applied for:

- Pre-treatment of seawater or brackish water

- Daily operations in aquaculture ponds

- Emergency response during Vibrio outbreaks

Integration with UV, RAS, and intensive aeration

Conclusion: A New Chapter in Indonesian Aquaculture Biosecurity

Electrolysis Cakra offers a pond water sterilisation solution that is:

- Science-based

- Field-proven

- Cost-effective

- Environmentally friendly

- Supports sustainable aquaculture

Test results from UK BAP Samas confirm that electrolysis technology is no longer a concept but a real solution to enhance the performance of Indonesian shrimp farming.